3-Arm Centering Reel

Handles coils up to 1828 mm in diameter, with standard weight capacity of 13.5 metric tons. Includes non-contact O.D. sensing for back tension control.

Variable Speed Straightening Machine

Equipped with two sets of pinch rolls. 16-roll straightening group, one overshot roll with large visual position indicator and an adjustable catenary to provide support for free loop of material.

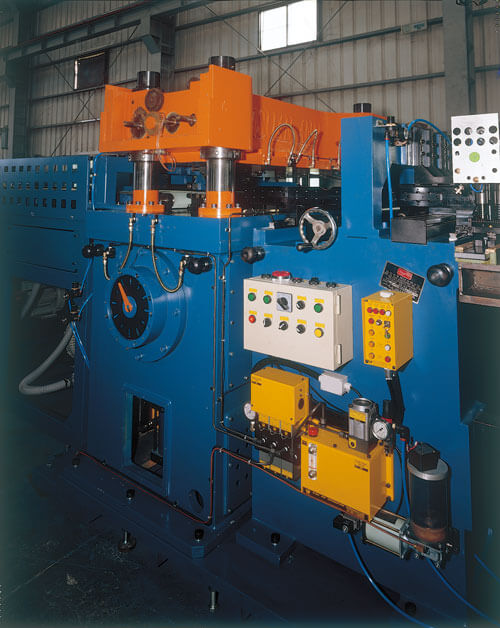

Electric Drive Feeding & Cutting Off Machine

Feed and cutoff machine produces lengths from 457mm to 1206mm, micro-adjustable in 0.025mm increments via electronic selection. Shear handles both straight-cut and scroll-cut dies.

Master Display Programming Panel

Provides faster, easier setting of operating parameters, as well as accurate accounting and status of sheets. Simplifies operation and troubleshooting for the operator.

Sheet Stacking and Classification System / 4 Station Heavy Duty Stackers

Automatically classifies and separates prime sheets from reject between prime piling stations when full stack count is reached. Provides continuous line operation until coil depleted.

Electric Panel with Air Condition

With air conditioner, extend the panel lifetime even longer.

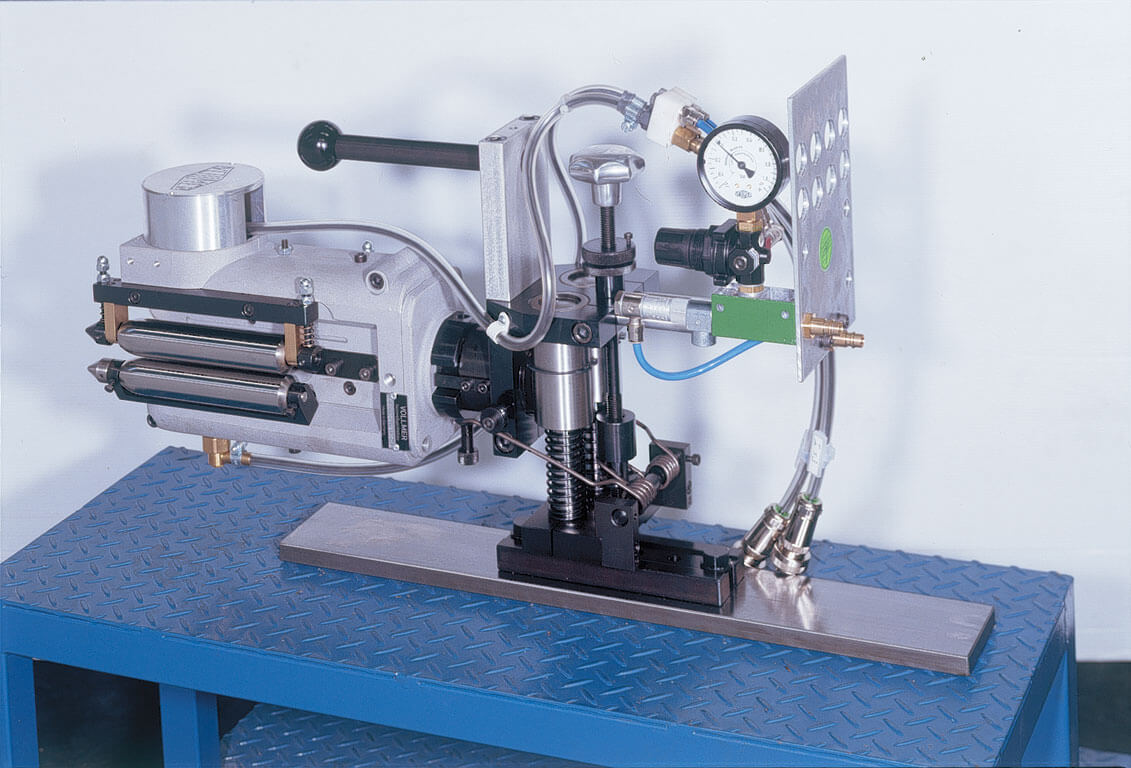

Motorized Gauge Table

Measures both straight and scroll-cut sheets. Digital indicators with instant in/mm conversion allow valuable data to be collected for improving quality control.

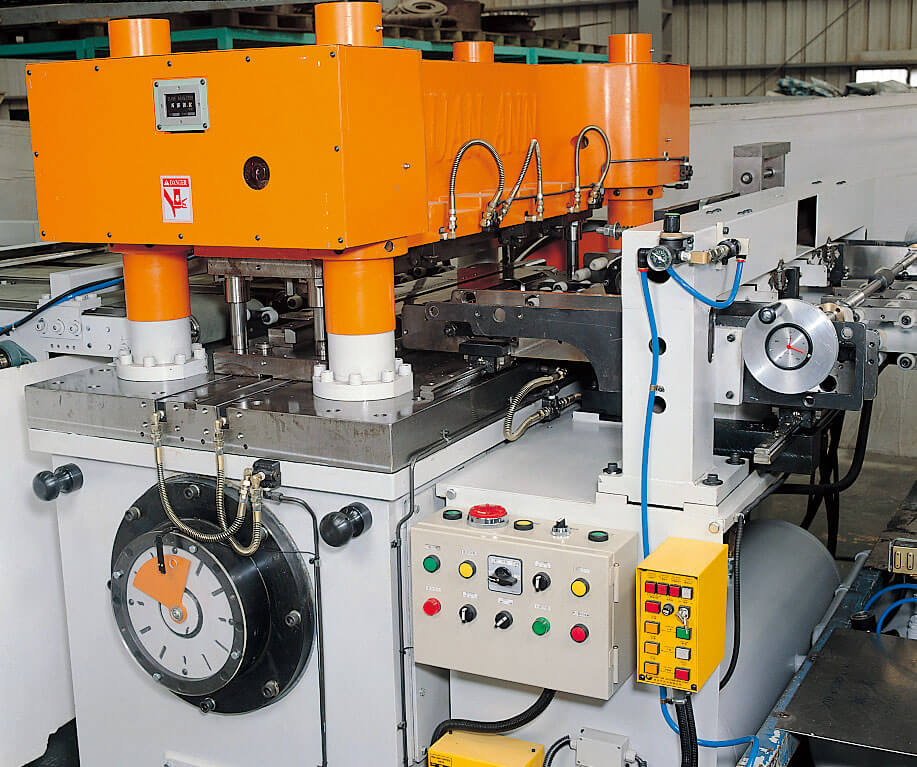

Quick Die Change

Enable the die change more faster, increase the capacity.

Thickness Gauge System

To ensure the correct thickness

Pin hole Detector

To eliminate the defective sheet, more reassuring of the quality.

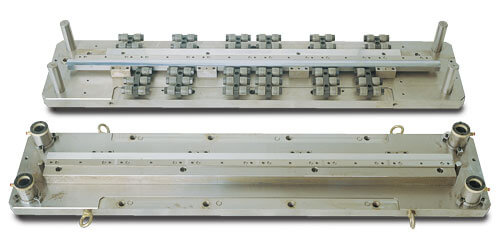

Carbide Cutting Die (Straight or Scroll Die)

We supply various dies upon your request.

Downender Coil Loading Cart

Complete with all electrical and hydraulic equipment for performing the required functions.

Light Rail System

Discharge and rail transport automatically after full pallet.

OPTIONS

OPTIONS