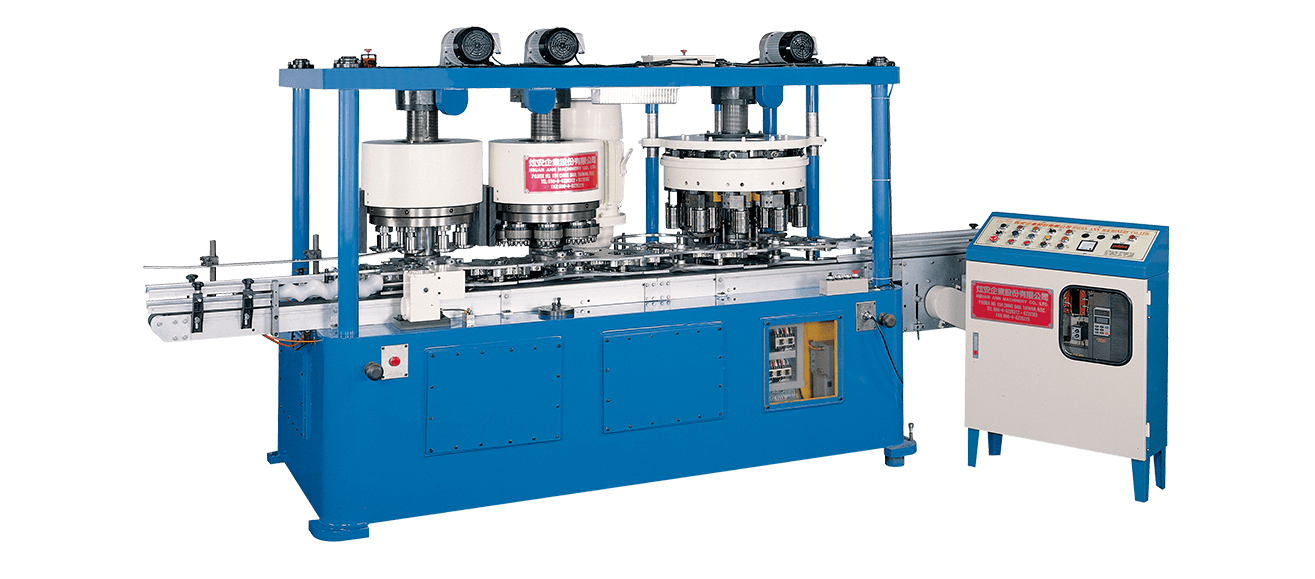

SJA-764A Automatic Necking Spin-flanging Beading Machine

-

Features

- 1.Straight conveyor for convenient material infeed and outfeed,reducing parts change when can type is changed, Avalable for necking--flanging--beading, flanging--beading or necking--flanging.

- 2.Powered elevation fives convenient adjustment for can height variation.

- 3.Specially designed transmission system for extremely smooth running and minimum wear on parts.

- 4.Newly designed round mold suits thin or thick sheet, with maximum stability of beading ring.

- 5.Fully automatic operation makes this machine ideal for online operation.

- 6.The parts that come in contact with the can bodies are hard chrome plated or coated with wear resistant media to prevent scratching.

- 7.Employs an imported Japanese Plc Controller, providing easy operation.

- 8.A forward/reverse switch is provided for convenient running tests of the machine.

- 9.The can infeed stops automatically if abnormal motions occur.

- 10.Vertically mounted motor saves space.

Plc Controller

The machine employs an imported Japanese high performance Plc Controller providing maximum operation convenience.The Plc Controller offers the following function:

- 1.Machine speed display.

- 2.Can counter.

- 3.Warning functions-Damaged Inventor, jammed conveyor,tripped clutch.

-

Specifications

Model Unit SJA-764H SJA-764A SJA-764SA Head 12H-12H-15H 8H-8H-10H 4H-4H-5H Range of can diameter 202D-401D 202D-401D 202D-401D Range of can height mm 90-190 90-190 90-190 Entrance capacity per min cpm 650-900 400-600 200-300 Horsepower required HP 20 15 15 Floor space mm 4150x2080x1800 4150x1330x1800 4150x1330x1800 Feed height mm 850 850 850 Discharge height mm 850 850 850 Net weight (approx.) kgs 8500 7200 6500 All specification, design and characteristics shown on this catalogue are subject to change without prior notice.